PETG

Features

- Easy formability

- Toughness

- Shiny surface

- Good machinability

- Food safe

About PETG

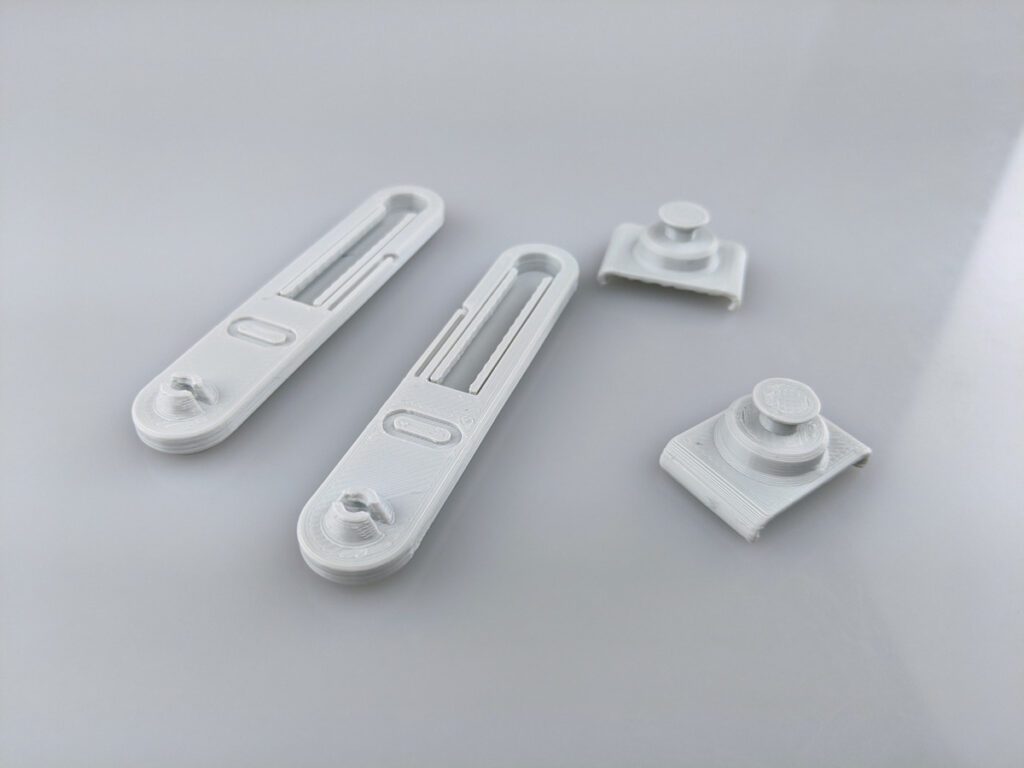

PETG (Polyethylene Terephthalate Glycol) is a glycol-modified version of PET plastic. It has the similar strength and durability of ABS, is easily machined, and is used for FDM 3D printing as well as other manufacturing technologies.

Properties

| Property | Value |

|---|---|

| Heat deflection temperature | 157°F (69.4°C) |

| Density | 1,27 g/cm³ |

| Tensile Strength | 7,700 psi |

| Flexural Strength | 310,000 psi |

| Shrink Rate | 0.3 – 0.8% |

| Water absorption (immersion 24 hours) | 0.20% |

Description

PETG is plastic that is strong and durable like that of ABS but absolutely harmless to human health. PETG is made with one of the most common synthetic materials – polyethylene Terephthalate (PET), which is modified with Glycol. Thanks to this, PETG is much tougher, stiffer, clearer and easier to use in 3D printing and machining than PET. Also, the modified plastic does not crystallize and becoming breakable. PETG can be used instead of polycarbonate (PC) for CNC machining as it can form a clear plastic material with almost the same impact strength as PC but much more cost-effective. PETG can also be used for hot line bending and welding.https://www.youtube.com/embed/U5qS9GiAYuc

Common Uses

- Toys

- Protective parts

- Mechanical parts

- Medical tubes and bottles

- Containers for food/beverages

Advantages

- High strength

- Chemical resistance

- Resistance to staining

- High impact-resistance

- Low thermal expansion

- Low moisture absorption

- Excellent machining characteristics

Disadvantages

- Can be weakened under UV light