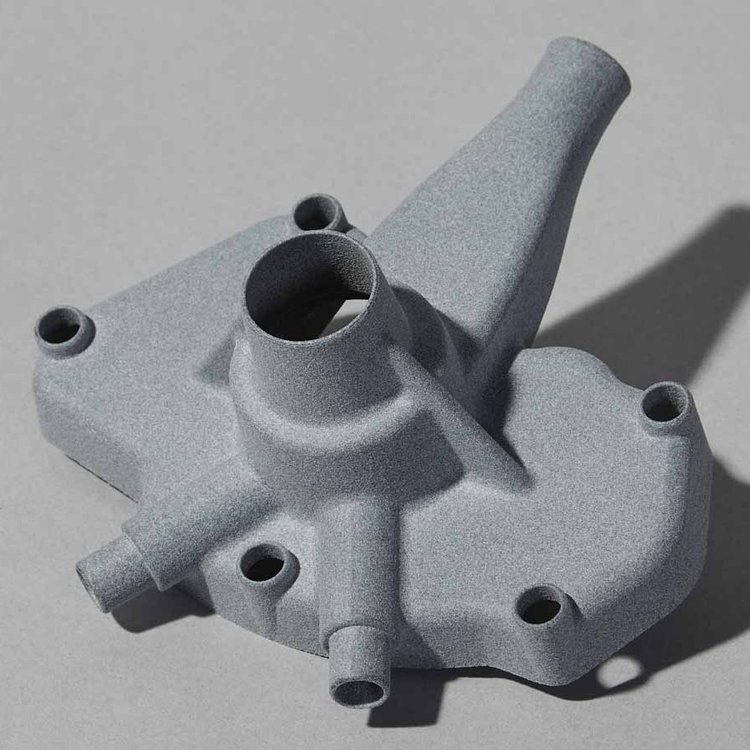

PA12 NYLON (MJF)

Features

- Durable material

- Smooth surface

- Chemically resistant

- Temperature resistant

- Food safe

- Stable in demanding environments

- Detailed resolution

- Suitable for end-use parts

- Biocompatible

- Low coefficient of friction

PA12 NYLON (MJF)

MJF PA12 Nylon is a robust thermoplastic with excellent mechanical properties. Engineered to produce end-use parts and functional prototypes, this strong, accurate, temperature, and chemically resistant material is ideal for volume production, replacing injection moulded parts.

Description

Mechanical properties

Durable, strong and mechanically stable. Due to the smaller particle size, MJF PA12 Nylon produces parts with higher density and lower porosity than SLS.

Chemical resistance

MJF PA12 delivers good chemical resistance to water, oils, greases, aliphatic hydrocarbons, and alkalies. MJF parts are compatible with most paints, primers and adhesives.

Flexibility

MJF PA12 parts with 1mm wall thickness display flexibility while thicker features, over ~3mm have higher stiffness. The versatility of PA12 material makes it ideal for dynamic applications.

Temperature resistance

MJF PA12 Nylon parts have good temperature resistance. Thick parts will remain dimensionally stable in temperatures close to 175 °C, while thin parts will start to soften and lose their shape when temperatures exceed 95°C.

MJF PA12 NYLON FINISHES

All MJF PA12 Nylon 3D prints start their life with a ‘Natural Grey’ finish before post-processes alter their appearance and surface properties. MJF PA12 offers several finishes to meet varied requirements when considering different polymer components’ desired aesthetic and mechanical properties.

| Mechanical Properties | Test Method | Value |

|---|---|---|

| Tensile Strength, max load, XY | ASTM D638 | 48 MPa |

| Tensile Strength, max load, Z | ASTM D638 | 48 MPa |

| Tensile Modulus, XY | ASTM D638 | 1800 MPa |

| Tensile Modulus, Z | ASTM D638 | 1800 MPa |

| Elongation at Break, XY | ASTM D638 | 20% |

| Elongation at Break, Z | ASTM D638 | 15% |

| Flexural Strength (@5%), XY | ASTM D790 | 65 MPa |

| Flexural Strength (@5%), Z | ASTM D790 | 70 MPa |

| Flexural Modulus, XY | ASTM D790 | 1730 MPa |

| Flexural Modulus, Z | ASTM D790 | 1730 MPa |

| Izod Impact Notched (@ 3.2 mm, 23°C) | ASTM D256 – A | 3.5 kJ/m2 |

| Thermal Properties | Test Method | Value |

|---|---|---|

| Heat Deflection Temperature @ 0.45 MPa @ 1.82 MPa | ASTM D648 – A | 175 °C 95 °C |

Common Uses

- Toys

- Protective parts

- Mechanical parts

- Medical tubes and bottles

- Containers for food/beverages

Advantages

- High strength

- Chemical resistance

- Resistance to staining

- High impact-resistance

- Low thermal expansion

- Low moisture absorption

- Excellent machining characteristics